We decided to separate this from the rest of the pipeline construction process because it’s a very specific process with it’s own equipment within the overall construction.

We decided to separate this from the rest of the pipeline construction process because it’s a very specific process with it’s own equipment within the overall construction.

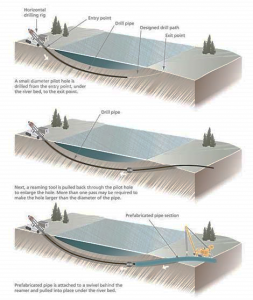

Horizontal directional drilling (HDD) is used to bore and install pipelines under flowing rivers. For rivers that don’t freeze and have heavy flow a “trenchless HDD” method is used – which means they basically drill a hole from one side of the river to the other, instead of damming or diverting the waterway to dig a trench.

HDD Rig

This setup means drilling pads and work spaces are set up on either side of the river. How far from each bank depends on how deep the pipeline must be drilled and the resulting curvature.

Pipe stringers

The process requires specialized, very expensive heavy equipment including an HDD rig, as well as pipe stringers. The HDD is used to drill a pilot hole, which is enlarged with each pass until it’s large enough to pull the pipeline (already strung and welded) back through to the other side.

Altogether, once started, the process is completed relatively quick.

Overhead of drilling pad

The best moment for intervention is before the drill makes it’s first pass.